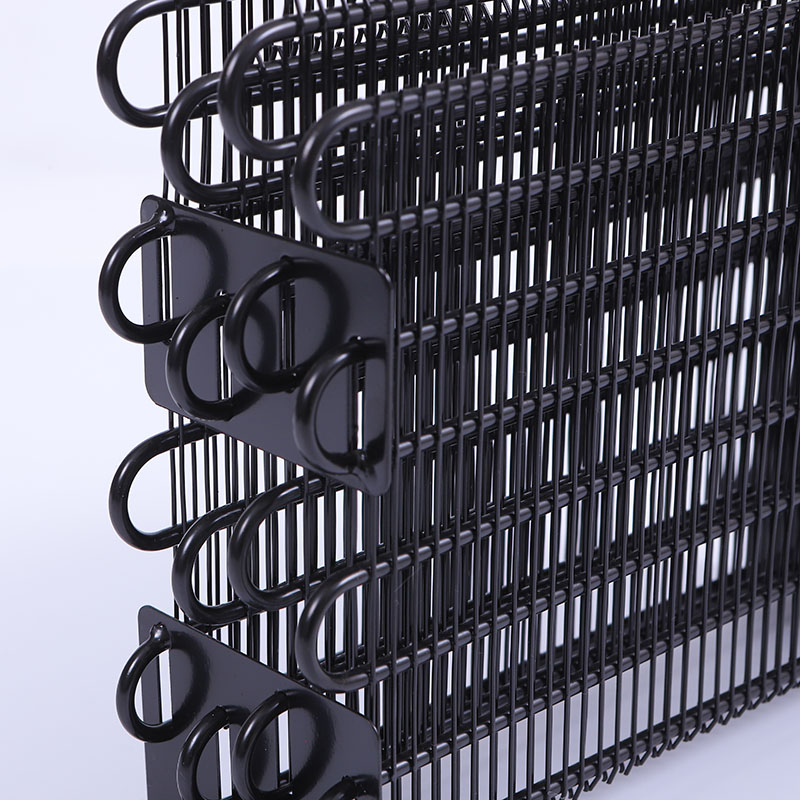

Air-cooled freezer condenser

Our condenser uses rolled welded steel pipes ( φ 4.76- φ 8, wall thickness 0.7mm) and low-carbon steel wire( φ 1.0-1.6mm) as the main raw material. The steel plate bracket adopts SPCC steel plate, with a thickness between T=0.6-2.0mm, ensuring the stability and load-bearing capacity of the bracket. In addition, our condenser adopts a curved structure design of a line tube condenser at the bottom, making the entire condenser structure more compact and conducive to improving space utilization.

Our air-cooled freezer condenser fully considers the influence of steel wire spacing in its design. A reasonable steel wire spacing (≥ 5mm) ensures a large heat transfer coefficient and improves the heat dissipation effect of the condenser. When the spacing between steel wires is large, air flow can be fully developed, resulting in better heat conduction. Thus the heat transfer coefficient is about 50% higher than that of the flat plate type and 10% - 15% higher than that of the louver type.

Our company has over 10 years of experience in the production of wire tube condensers, focusing on providing customers with high-quality products and services. Combining our unique curved tube condenser design, this condenser can fully utilize its heat dissipation effect and provide continuous and stable cooling performance for your freezer. By choosing our air-cooled freezer condenser, you will enjoy an efficient and stable cooling experience, making your life and work even better. Seize the opportunity to upgrade your freezer and invest in a trustworthy condenser!

RoHS of bundy tube

RoHS of low carbon steel